Superchargers

Whipple 2.9 Litre Supercharger Kit for VE/VF Commodore & 5th Gen Camaro

Whipple Factory Designed 2.9 Litre Supercharger Kit for VE/VF V8 Commodore & 5th Gen Camaro

| Region | Description | Freight USD | Rural Freight USD |

|---|---|---|---|

| Auckland |

Auckland Auckland Region |

$0.00 | |

| Whangarei / Hamilton |

Whangarei / Hamilton Up to Whangarei / Down to Hamilton |

$0.00 | |

| North Island |

North Island Rest of North Island |

$0.00 | |

| Christchurch |

Christchurch Christchurch Region |

$0.00 | |

| South Island |

South Island Rest of South Island |

$0.00 | |

| Rest of the World |

Rest of the World Rest of the World Freight |

$498.00 |

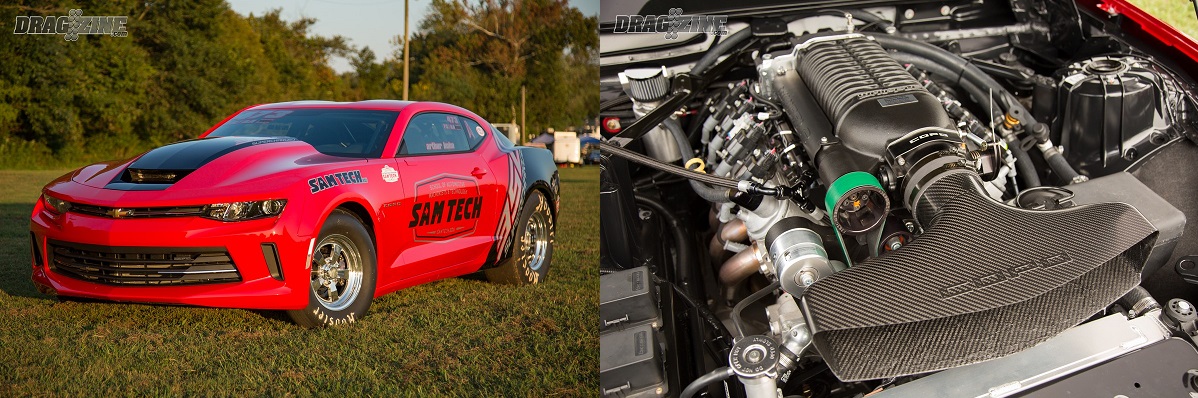

XAIR PERFORMANCE WHIPPLE 2.9L VE/VF and 5th GEN CAMARO V8 SUPERCHARGER KIT - IN STOCK!

The Whipple 2.9 litre VE/VF Supercharger Kit has a OEM Factory Part Finish and comes with XAIR MAFLESS OTR Direct Flow Air Intake, 3 Bar Map Sensor, 65 pound Injectors, Oversized Alloy Intercooler Reservoir which includes an integrated separate replacement window washer bottle tank that sits behind the front bumper, Massive air-to-water Heat Exchanger for ultra low manifold air temps for consistent power and all the hardware necessary for a simple installation.

Whipple 2.9 features a Gear Driven Rear which eliminates power robbing belt slip.

With the Standard Whipple 4.0" Diameter Top Pulley this will run approximately 9-10psi boost on a Factory Standard VE/VF V8 Commodore / 5th Gen Camaro and be good for approximately 470kw (L77 6.0) and 490kw (LS3 6.2). Add Headers, High Flow Cats and Twin 3" Exhaust (less restriction) and boost will drop down to approximately 7-8 psi with a power increase to 550kw (6.0) and 570kw (6.2). Add our XAIR Street Blower Camshaft and power increases to approximately 570kw (6.0) and 590kw (6.2) and boost drops by a further 1psi. For cars equiped with Headers/Exhaust/Camshaft as above we now have an option of increasing Boost back up to 9-10 psi by changing the top pulley to the smaller size. This increases power to 630-640kw (6.0) and 650-660kw (6.2). We do not recommend going to more than 640kw (530kw at the Rear Wheels on Hub Dyno) on Automatic Cars to protect transmission. .

The Whipple 2.9 Superchargers are designed to support/flow up to 1200hp with a built LS Engine. If you want some big numbers then we now have a 3.5" Top Pulley and 80 pound Injector option which will see around 11-12 psi with 2" Primary Headers and 675kw (900hp) on BP98 or 700kw (940hp on E85). Note : All models require a Fuel Pump upgrade for this.

Fits all Holden and HSV VE and VF V8 / 5th Gen Camaro with 6.0 L98, 6.0 L77, 6.2 L99 and 6.2 LS3 Engines. Will fit E1 HSV if Heads are changed to Rectangular Port style.

All VE cars need to run our XAIR VE Twin Nostril/Twin Exit Vent Bonnet as the stock bonnet doesn't have enough clearance. E2 and E3 HSV require our E2/E3 Specific ZL1 Style Bonnet.

All VE cars will require a Fuel Pump upgrade except for some late 2011 onwards E3 HSV's which have the bigger VF Pump. Early VE will also need the newer L77/LS3 Waterpump.

Since 1987, Whipple Superchargers ™ have been the pioneers and leaders of twin-screw supercharging. Whipple was the first to bring positive displacement technology to fuel injected, emissions legal GM applications. With over 26 years of GM twin-screw supercharging experience, Whipple's team have now engineered the most powerful intercooled twin-screw SC system available today for your VE/VF Commodore.

With all the latest technology, the all new Whipple system makes more power than any other positive displacement supercharger system on the market. The new Whipple system is 100% complete and is designed for stock engines but has enough capability to work with heavily modified engines. The all-new system features Whipple's massive oversized air-to-water intercooler for unmatched cooling capacity, a unique front feed W175ax (a whopping 2.9 liters) integrated Whipple twin-screw supercharger that reaches 99% volumetric efficiency and industry leading power potential.

The unique intercooled bypass system offers better acceleration and less than 1hp of consumption during cruising for excellent fuel economy. The system also includes high-flow fuel injectors and aluminum high flow intake manifold. While others claim, Whipple Superchargers simply deliver more power per pound of boost than any other supercharger on the market today.

Not all front inlet systems are created equal. Unlike other Front Inlet Superchargers the Whipple front inlet system is not restricted by a 93mm inlet system which severely limits your potential power gains. The Whipple SC system uses a unique 112mm round (round flows significantly more then oval or rectangle) inlet for nearly 1800cfm capacity (1200hp).

The Whipple kit also comes with a set of flow matched Bosch 65 lb/hr fuel injectors that are rated up to 90psi of fuel pressure giving you the capacity for far greater power levels then standard systems.

Stage 9 running stock Boost Pulley @ 8.6psi with Headers, Exhaust & XAIR Cam (see Power Packages)

Exclusive Features

- The most powerful 50-state USA emissions legal Supercharger option available

- No other upgrades required, just massive power right out of the box

- Or even more Power with upgraded Boost Pulley, Headers & Exhaust.

- Front entry W175ax (2.9 liters) Whipple twin-screw supercharger that significantly outperforms competitions 1.9L and 2.3L roots-type systems

- Front feed supercharger utilizes precision ground helical cut gears vs a problematic belt.

- Integrated casting to minimize bolt on pieces, adapters, leaks and flow restrictions

- Integrated Crusher ™ venturi shaped inlet for maximum airflow capacity and minimal rotor cavitation

- Integrated Crusher ™ 112mm round inlet outflows smaller 90 and 93mm inlets such as other Eaton based systems

- Integrated Crusher ™ 112mm round inlet for optional 102mm throttle bodies

- XAIR Plastic OTR High Flow Direct Air Intake (or optional Gloss Black Gelcoat or Carbon Fibre) for increased velocity and lower inlet temps vs. steel and aluminum tubes

- Integrated design allows for oversized intercooler core compared to other smaller intercooler cores giving Whipple lower air charge temps which allows more boost and timing to be run on pump gas

- Massive air-to-water aluminum bar-plate intercooler offers more cooling than any other positive displacement system available

- Whipple Superchargers massive oversized intercooled air-bypass system for industry leading reduction of burst knock and incredible fuel economy, no ridiculous fabbed steel tubes or systems that circulate hot air

- Self-contained oversized oil system for dramatically reduced oil temps in even the most demanding conditions

- Exclusive 3x5 rotor combo for significant increase in airflow under the curve than less efficient 4x6 rotor combo

- Zero turn inlet allows for decreased induction losses when compared to rear inlet systems and 180deg bends

- Center discharge port for better cylinder to cylinder distribution than other twin-screws with billet adapters and forward facing discharge

- Discharge down design allows for less pressure loss which gives more power at lower boost levels

- Top mount design allows for cooler operation then upside down SC's that conduct heat from engine and are trapped by runners and covers, causing hotter manifold temps and less power per pound of boost

- More boost at the "hit" than any other twin-screw

- Flat torque curve for incredible acceleration

- Oversized heat exchanger for incredible intercooler water temps

- Fits under factory bonnet

- No internal modifications required

- Completed installation looks factory installed

- Kits come complete with all necessary parts and hardware for installation

- Unique oil level sight glass for easy oil level and quality check, no dipstick to bind or misread

- Plug and play wiring with male and female connections

- High flow fuel injectors included

- Proven 6-rib belt system with heavy duty spring loaded tensioner and adjustable idler system

- Optional 10-rib belt system with matching billet pulleys

- Stainless steel jack-shaft with unique plastic cover (or optional carbon fibre) for increased safety

- OEM quick connect fittings for easy installation, no ugly brass or steel fittings on the SC

- Complete kits, Tuner kits and Hot Rod kits are available

- Available in wrinkle black, polish or any custom color

- Easily upgradeable with bigger throttle bodies (102mm or 109mm)

- Instant boost at the touch of the throttle

- 3 minute pulley changes

- 1 year warranty

- Optional 3-year 60,000 km warranty

Supercharging - Various Methods vrs Turbo

Forced Induction Designs

Not all superchargers are created equal, and supercharging isn’t the only way to add forced induction into the equation. An internal combustion engine is in essence an elaborate air pump, and the idea behind forced induction is to push more air through the system with each combustion event. In theory, more air combined with more fuel should equal more horsepower.

Turbocharging has long been an alternative to large, naturally aspirated motors, and in recent years many automakers have turned to this method to add performance while minimizing the impact on fuel economy to get it. Turbocharging, like supercharging, forces more air into the combustion chamber, in turn causing a bigger bang. But unlike superchargers, turbos aren’t belt driven. Instead their turbines are motivated by the engine’s exhaust gas. While this has a benefit of improved efficiency versus supercharging during low RPM cruising, it means that the engine’s power delivery isn’t linear since the turbochargers only spool up and make power once that engine hits a certain range in the powerband.

Superchargers, on the other hand, are belt driven and therefore create boost whenever the engine is operating. While this isn’t as frugal on fuel, it means the engine’s power delivery is more linear throughout the rev range, in turn behaving more like a naturally aspirated motor would.

In the realm of modern superchargers, there are three main design approaches: Roots type, centrifugal, and twin screw. Each has its advantages and drawbacks, and both tuners and automakers utilize all three designs in different applications.

The Roots of Supercharging - Roots type superchargers have a history dating back to the late 1800s, when the Roots brothers designed a system to serve as an air conveyer for mine shafts. More recently, roots type superchargers have taken the forms that you’ve likely seen popping out of the hoods of drag race cars with bird catcher-style hood scoops. While their simple design has made them a popular choice over the years, they typically lack the efficiency of newer alternatives.

Centrifugal Motion - By contrast, centrifugal superchargers function more like a belt-driven turbocharger, utilizing a compressor wheel (much like a turbocharger’s) to force air into engine. But rather than using exhaust gases to spool the compressor, it’s done by an engine accessory belt. While centrifugal superchargers certainly have a use case in modern applications, particularly where engine bay packaging is tight overhead, they typically take longer to ramp up to their full boost levels as opposed to a twin screw or roots style supercharger, which produce large levels of boost almost immediately.

Derived from Roots type superchargers, twin screw superchargers improve upon the design by compressing the air before it goes into the motor, rather than simply pumping more of it in as Roots type superchargers do. The design yields significant improvements in overall efficiency too, resulting in less heat, consistent performance throughout the rev range and tons of low-end power, the latter of which is particularly desirable in street driven vehicles.

For those reasons, twin screw style superchargers have become the go-to design for OEM high performance applications, most recently with Chevrolet’s sixth-gen COPO Camaro and Dodge’s supercharged 6.2-liter Hellcat V8. Whipple supplies the 2.9-liter twin screw supercharger used on Chevrolet's COPO Camaro drag car.

For those same reasons, companies like Whipple utilize a similar twin screw design for their aftermarket products as well. And as we’ll explain below, Whipple’s twin screw supercharger design differs from GM’s roots-style approach with the LSA, LS9 and new LT4 in some important ways.

Development and Design - When a company develops a supercharger for a new vehicle, there’s a multitude of factors that must be considered beyond sheer output. “We basically start with a car, an engine and the CAD data of the vehicle,” says Dustin Whipple of Whipple Superchargers. Getting the maximum amount of air into the engine is only one part of the supercharging formula - it also has to fit into the vehicle in question with minimal additional modification (or, preferably, none at all), and it also has to have enough thermal efficiency to avoid succumbing to heat soak over a reasonable period of time. Whipple's design is robust enough that additional headroom has been built in for further performance modifications down the line.

“From there we begin with a design review, understanding what can fit and what can’t, so we can start development. Once we’ve come to an understanding of what will be best for that application, we begin all the work in CAD. From there, the basic design gets done to maximize all areas.

“We use CFD software to help with inlet design and airflow, then we work with our intercooler vendors to come up with the optimum intercooler size and type as we modify both the air and water side of the core depending on the application. From there, we then 3D print sample parts to mock up in the vehicle and on the engine, ensuring fitment, clearance, ease of installation, etc. Once we’ve done this, made changes, we go to castings and prototype testing.”

Superchargers tend to generate a lot of heat, and heat is the enemy of performance when it comes to supercharging. While getting a lot of air into the motor is important, making sure the system can maintain consistent output through proper heat management is just as pivotal, otherwise power tends to drop off precipitously as heat soak sets in.

“What separates us from most is that not only do we go the extra mile to maximize airflow on both the inlet and out of the compressor, we also use larger, more efficient intercooler cores that truly maximize cooling. We design them with the mindset that the base power level is only the first stage, meaning we build significant extra capacity for power, airflow, and thermal efficiency. Many miss this and only maximize for base power, leaving it less efficient or ideal for later modifications.”

For the 2016-17 Camaro SS, the result is a 2.9 liter twin screw supercharger system that simply outperforms the established alternatives. “Compared to a centrifugal, this system offers instant boost for increased drivability, more tip in torque, and a much cleaner installation,” Whipple says. “Most centrifugal systems require cutting to get the air tubes to the front of the vehicle, as well as having the air filters above the headers.”

And compared to GM’s Roots type Eaton TVS supercharger used on the LT4, Whipple’s system doesn’t have to spin nearly as fast to make similar levels of boost, in turn reducing the internal temperatures that GM has struggled with during prolonged road course use with the C7 Corvette Z06.

“Compared to the Eaton, we have far more capacity – 2.9L is 26 percent more capacity than the 2.3 liter, and more than 50 percent greater capacity than a 1.7 litre or even LSA 1.9 litre,” Whipple points out.

“This lowers the compressor speed over 2000 rpm, allowing you to get more optimal power, as well as having more capacity in the future. The twin screw is a true compressor, giving it less leakage in boost applications, lowering power consumption and discharge temp. Therefore the Whipple supercharger stays cooler, longer with less heat soak.”